Think Tank

How Distributors Can Improve Fleet Performance

Photo: iStock.com/vitpho

Fleet performance can make a financial and competitive difference for distributors. Route planning is an essential element in that performance.

Distributors know this instinctively, but experience shows that fleet performance varies widely across distribution organizations, even for similar businesses using the same route planning solutions. The advantage for top-performing distributors is considerable: They require fewer resources, have shorter planning cycles and better productivity. Results include:

- A 50% reduction in the number of planners required;

- Planners being able to plan 70–100 vehicles;

- Minimal manual interventions (fewer than 5% of stops reworked);

- Reduced time spent planning (less than one hour), resulting in later order cut-off times, and

- An ongoing fleet productivity improvement of 2%–5% annually.

Why the performance variation? Poorer performers are not employing route-planning best practices for measurement, processes, organization or education. Six points tell us that a distributor isn’t using best practices:

- No performance baseline and no financial weighting of metrics;

- Planners considering the planning process as more of an art than a science;

- No visibility into the effectiveness of planners;

- Decentralized planning and a lack of planning process control;

- Missing or inaccurate planning data, and

- Low planning expertise

The good news is that all these challenges have straightforward solutions. Following are key route-planning best practices that turn poor fleet performers into top ones:

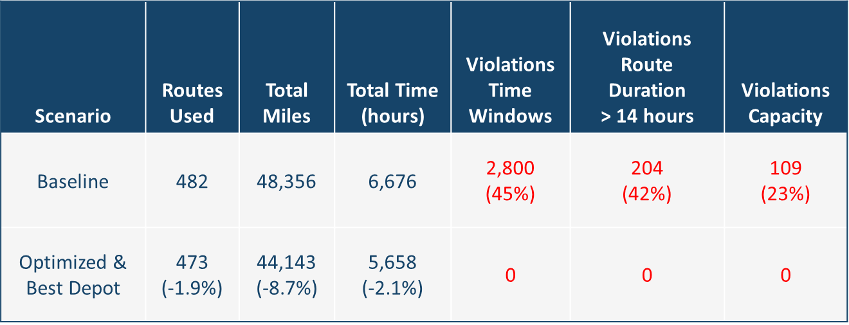

Establish a performance baseline and financially weight operational metrics. These two points are fundamental to implementing route-planning best practices. However, due to manual processes or legacy solutions, it’s not unusual for distribution organizations to lack metrics or data to provide a comprehensive view of their performance. Use a route-planning tool that combines route execution and GPS-based mobile applications to establish a performance baseline. Then focus on improvement (see Figure 1). Weighting metrics financially is important, because not all metrics have the same financial value, and improving performance involves making trade-offs between miles, resources and vehicles. For example, one mile might cost 80 cents while a driver hour may cost $40 an hour and a vehicle $100,000 annually; therefore, it might make sense to drive more miles if the result is less time and vehicles.

Figure 1: Balanced performance scorecard example

Source: Descartes

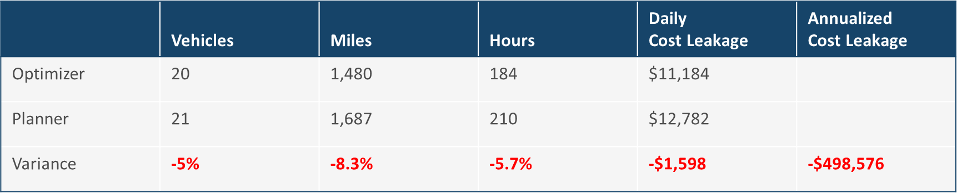

Track and compare plan results by planner versus route optimizer. Route planners will make subjective changes to the optimized plan based on “tribal” knowledge, which can negatively impact financial performance. The impact of those changes needs to be measured (see Figure 2). This is especially the case for route planners coming from manual or legacy system route-planning environments. For example, the route planner may want “petal” routes but doesn’t understand that the optimizer determined that non-uniform routes were the most efficient. If the route planner adjusts the routes for greater uniformity, they will sacrifice efficiency gains.

Figure 2. Planner plan versus optimizer plan performance analysis example

Source: Descartes

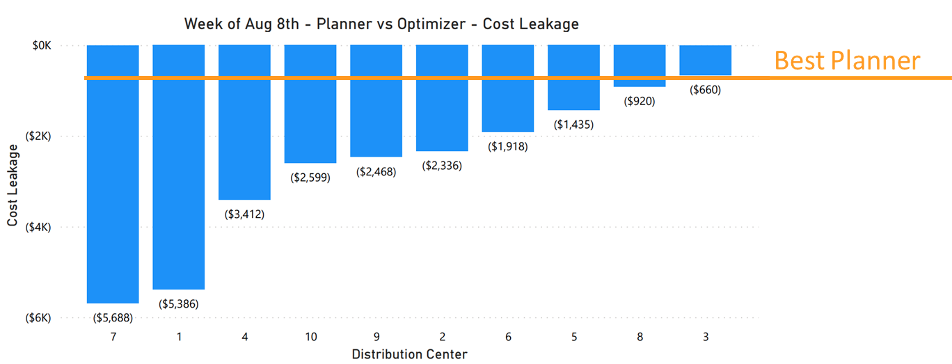

Eliminate planner performance variability. Variances in planner performance are costing your organization money. There’s a significant difference in the quality of route plans across the planners (see Figure 3). Because planning isn’t as simple as pushing a button, distribution organizations need to identify the best planning process, document it and institutionalize it across the planner community. The results will be higher plan quality and less performance leakage.

Figure 3: Variance in route plan performance by planner example

Source: Descartes

Make every planner your best planner with automation. Modern route-planning systems have automation capabilities to embed planning best practices and execute without human intervention. This approach makes planners more productive because they focus on the plan review and exceptions, ensures planning consistency and better results, minimizes planning resources, and reduces planning latency.

Move to centralized planning. For a long time, the common belief was that the planner had to be in the field to have the necessary local knowledge. This is no longer the case and, in fact, the best planning occurs when it’s centralized. Centralization builds greater domain expertise, makes more effective use of planning resources, improves planner productivity and allows for more focus on continuous improvement. Centralization also is less impacted by the loss of a resource and its replacement.

Constantly focus on data quality to drive better optimization results. One of the telltale signs of route optimization performance deterioration over time is the lack of maintenance of configuration and operational data. Failure to adjust the application as the business changes, or enforce quality standards on items such as dimensions and weights, will impact the optimizer’s performance. Planners can lose faith in the result and turn to more manual adjustments, causing performance to spiral downward. Data maintenance is a never-ending process; however, machine learning can help improve data quality by continuously evaluating actual performance data, and making recommendations or configuration changes that maintain or improve route plan performance.

Understand that training has a return on investment. To some degree, route planning is rocket science, and the knowledge that a planner has about route-planning techniques and systems directly impacts plan performance. Much effort is put into training the initial resources during implementation; however, over time, planners change and there’s often not the same level of training for the new ones. The situation is analogous to planning system enhancements when there’s no focus on education about new releases. Continuous training must be a fleet management cornerstone, and that’s one of the reasons why centralized planning consistently outperforms distributed planners.

It’s not rocket science to fully embrace rocket science. Route planning is the lynchpin of fleet performance. Fortunately, the path to improving route-planning performance is a logical set of steps that any distribution organization can apply to take their fleet. They include:

- Adopt fleet performance baselines that allow you to understand not only your overall performance, but also how each of your planners are contributing to it.

- Eliminate planner variability by creating best practice planning processes and automation.

- Centralize planning to create a critical mass of planning knowledge and a culture of continuous improvement.

- Be vigilant on data quality.

- Continually invest in training new and existing planners.

Chris Jones is executive vice president of industry with Descartes.