Think Tank

The Game-Changing Role of Graph Technology in Supply Chain

Photo: iStock.com/AerialPerspective Works

As they grow ever more complex, modern supply chains require comprehensive lifecycle orchestration.

Among the many challenges they face is integration of upstream and downstream partners. Companies typically use different management systems for multiple functions that fail to “talk” to one another. Hence, the impact of an upstream supply disruption isn’t easily traced to a downstream stockout. What’s needed is a system that enables dynamic visibility.

Traditionally, supply chains have depended on relational database management system (RDBMS) software and structured query language (SQL) to achieve visibility. Yet those traditional tools have failed to keep pace with the increase in complexity. Modern supply chains demand comprehensive oversight, near-real-time insights into relationships and interdependencies, and the ability to predict risks and create effective mitigation strategies. This, in turn, has given rise to the need for intelligent visibility, encompassing both structural and dynamic aspects.

Despite major advances, just 3% of companies have reached autonomous execution, and many still rely on predictive or prescriptive use of data (67% and 40%, respectively). Even with application programming interface (API) integration, the limitations of RDBMS highlight the need for solutions that offer quick insights into today’s non-linear supply chains.

From Structural to Dynamic Visibility

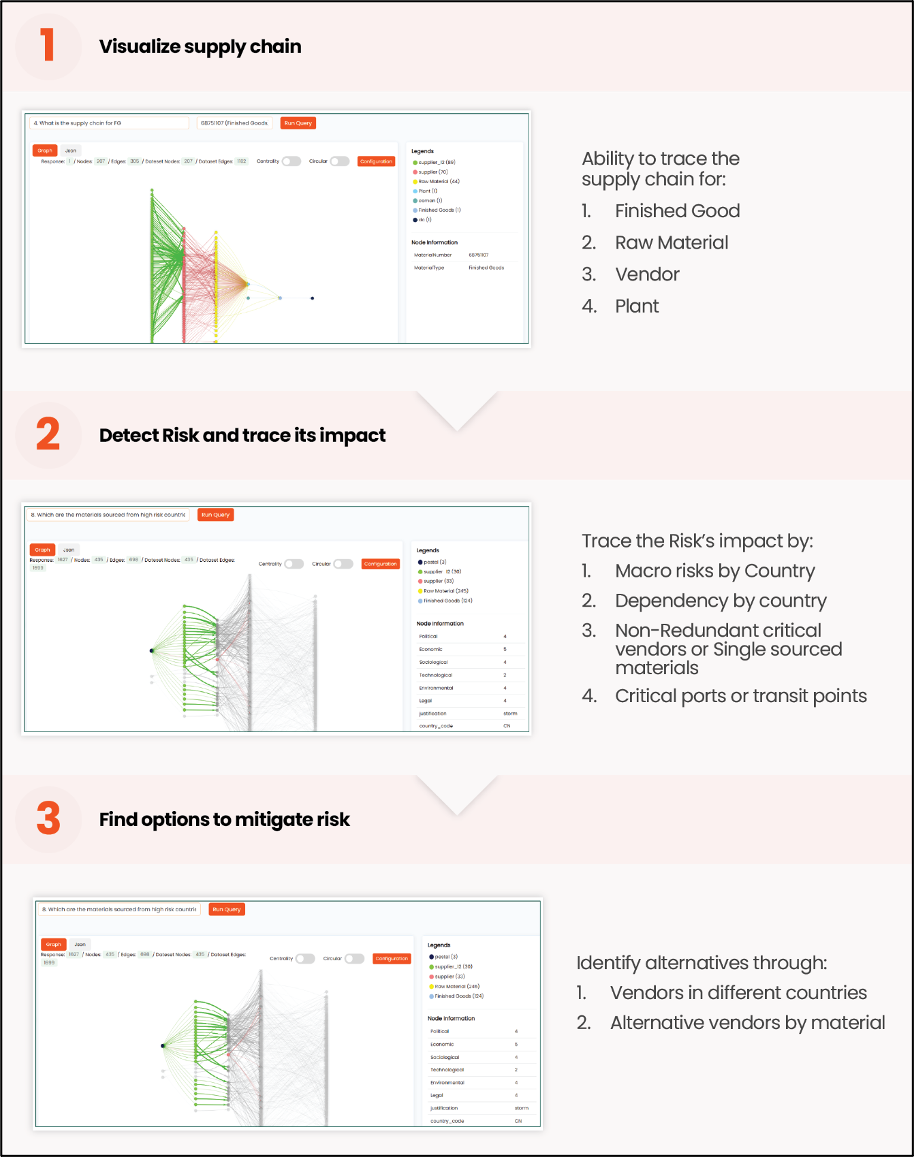

Shifting from structural to dynamic visibility is essential for companies looking to gain a competitive edge in their supply chains, and this is where graph databases come into play. Unlike traditional databases that use tables for data storage, graph databases represent data as nodes and edges, making them ideal for modeling complex networks like supply chains.

Furthermore, graph databases excel in querying connected data, allowing for quick identification of relationships, including tracing second-tier suppliers for specific product variants. They offer other significant advantages over relational databases, such as improved scalability for large and complex datasets, and flexibility in handling various data types — structured, semi-structured and unstructured. As a result, graph technology, which was initially popular in social networks (such as LinkedIn), is now proving indispensable for navigating the intricacies of modern supply chains.

Using data from enterprise resource planning (ERP) systems, quality and compliance documents, export data and more, graphic databases create 360-degree supply chain visualizations. Key capabilities that play a crucial role in understanding the network include:

- Betweenness centrality. Identifies potential bottlenecks by measuring the frequency at which a node appears on the shortest paths within the network. For example, do your goods flow through a specific port more than others?

- Degree centrality. Assesses a node’s load and dependency within the network, such as how crucial a warehouse is to a supply network.

- Regional dependence. Analyzes natural clusters within the network, highlighting areas of high interdependency. For example, are some of your vendors located close to each other?

These metrics help enhance supply chain visibility, enabling supply chain leaders to identify and counter risks and vulnerabilities. For instance, during disruptions such as natural disasters, graph databases can quickly simulate impacts across the supply chain, enabling timely evaluation of alternate scenarios and the implementation of effective mitigation strategies.

Riding the Wave of Graph Technology

With its growing adoption in various sectors, graph technology is predicted by Gartner to be central to climate change response and fraud detection, with 80% of data and analytics innovations adopting the technology. Major firms are also increasingly turning to graph technology, including hyperscalers and consultancies. Apart from end-to-end supply chain visibility, graph technology helps integrate data across silos. It enables quick simulations and insights for risk mitigation and optimization. And as supply chains expand, their scalability effectively captures complex data. Additionally, it enhances transparency and trust through live visibility, and aids in ethical sourcing monitoring.

The future of supply chain management is intertwined with advances in graph technology. It will help enterprises to analyze, understand and respond to complex data landscapes. Those equipped with a strong graph database tech stack will lead the race to agile and efficient supply chains.

Hemanth Holla is director, supply chain products, and Sudarshan NR is manager, supply chain, with Tredence Inc.