Photo: iStock.com/gorodenkoff

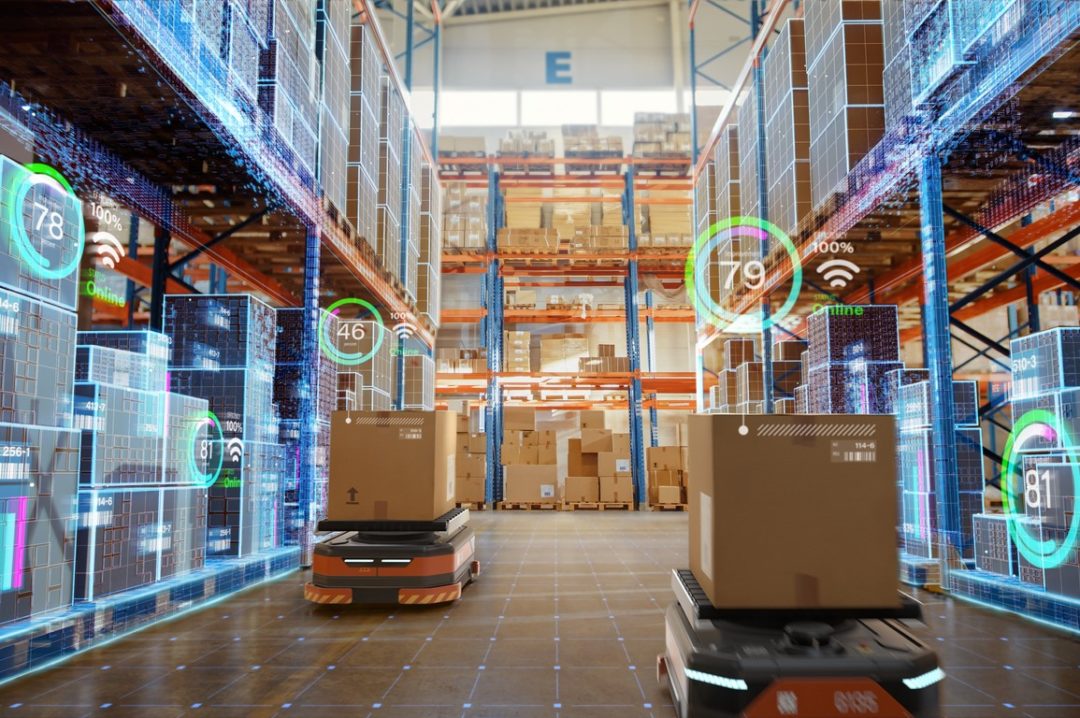

Getting the Most Out of Automating the Modern Warehouse

Automation has been touted as the key to ramping up warehouse efficiency in a time of rising demand and a chronic shortfall of labor. But it comes with its own set of problems.

Chief among them is the upfront investment required to equip a warehouse with robots and other modern-day systems that streamline and speed up operations while requiring fewer people on the floor.

It’s more than a matter of swapping out a human for a robot to perform a traditional task, notes Mor Peretz, chief executive officer and co-founder of CaPow, creator of a power-delivery system for robotic fleets. Today’s warehouse is a different animal, one that must fulfill multiple needs, from the movement of pallet-sized loads to retailers and distribution centers, to the processing of individual orders for e-commerce customers.

The labor squeeze is being felt country-wide, but is especially evident today in the Midwest and down into the southern states, Peretz says. Staffing levels in those locations still haven’t returned to pre-COVID numbers, with former warehouse workers seeking jobs that are less physically demanding and, in many cases, less monotonous.

Meanwhile, with the coming of sophisticated automation systems, there’s a need for a different kind of warehouse worker with a higher set of skills, especially when it comes to interacting with machines.

Automation doesn’t necessarily translate to greater efficiency. Many facilities that have acquired fleets of robots are still missing performance targets, Peretz says, due in part to a misalignment with operational needs and extensive downtime for maintenance, repair and charging.

Early enthusiasm for shiny new technology often fades with experience. After a couple of years of use, facility managers who initially had been thrilled with their new robots “were calling us, saying ‘Come put in your system because we cannot stand the downtime anymore,’” Peretz says. There’s a learning curve involved with the acquisition of automated systems, where “once you get it up to speed, you start to realize that you can improve it.”

Automation is supposed to save money in the long run, but first it has to be paid for upfront. As new systems enter the market, “the entry point in terms of pricing is becoming a concern,” Peretz says. “It’s not a premium feature anymore. It becomes part of the operation, and you need to account for that.” In addition, as robotic fleets grow in size, warehouses must contend with additional overhead, including the energy needed to run them.

One big benefit of robots is that they increase output by making possible operations around the clock, or at least an additional shift. Even then, though, the system “needs to operate to its full extent and not have any downtime,” Peretz notes. Running a 24-hour operation “becomes even more challenging, because then you can’t compensate for lack of energy by having a machine charged during a downshift.”

The answer is technology that charges the robots while they’re still moving and working. “We like to make sure that they don’t stop or deviate from their path,” Peretz says.

The full benefits of robotic warehouse automation are only realized when the units are deployed to their utmost capability, he says. In theory, robots should never have to stop, lacking the need for breaks, lighting, air conditioning and other features that are essential to the welfare of human workers.

The endgame would appear to be a “lights-out” facility without any human presence at all. “It is indeed a valid option,” Peretz says. “We see more and more facilities that are at least partly allocated for robots only.” Prime prospects include environments that are hazardous or inhospitable to humans, such as freezer areas. Warehouses that handle a limited range of products, or have few variations in putaway and picking, are also potential candidates for a people-free setting.

Most warehouses seeking to automate aren’t looking to jettison their entire human staff — at least not yet. Instead, they’re aiming to boost productivity by assigning the most repetitive tasks to robots, while people continue to perform in higher-level roles.

“Our intention is to increase the strength of each category,” Peretz says. And that requires understanding exactly what a robot can do, including how to derive the most payback from a substantial investment in modern-day warehouse technology.